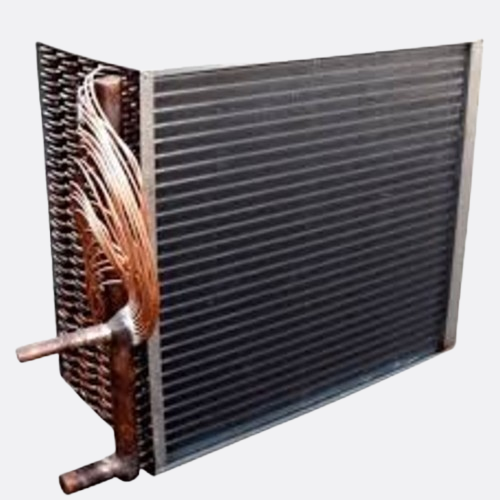

DX Coil

Caryair produce quality DX coil and Child water coil. as per customer specification. Caryair coils are OEM Product to many AHU Manufacturs and fan Coil unit Manufactures. Caryair system is a leader in the replacement Chill water coil and Dx coil Market. Caryair understand that many coils replacement are emergencies. we provide competitive quotes fast and all quotes include pricing for standard and expedited production circle. detailed coil as build drawing are provided during order entry for your final check and approval. our expert spend the extra time required to ensure the replacement is a perfect fit.

Chilled Water Coil

Water Coils can be used for EI. single purpose such as heating or

cooling, or their function can he alternated between heating and

cooling by changing the temperature of” the water Flowing through

the coil. Depending en the application, it may be necessary to use

a glycol mixture to prevent the liquid from Freezing. Sure fin Coils

water coils are engineered to operate at pressured up Le 250 PSIG

and temperatures up to 300F, but ancillary equipment such as

valves and lumps will often dictate lower operating temperatures.

All water coil are pressure ester at the factory with 451 PSIG of”

dry’ nitrogen.

most chilled water coils are designed with either 1/2″or 5/8″ 0.D tubes. However, there are an increasing number of

manufacturers who deign chilled water coils with 3/8 tubes, especially for coils that are for very low capacity (5 tons or less). Larger tubes are typically used because they keep the water pressure drop lower. However, the smaller tonnage coils usually have short lube lengths and, thus, inherently lower fluid pressure drops.

Construction Capability

- 5/8″ O.D. X .020″ copper tube wall thickness as standard

- V:” O .11 X copper tube wall thickness as standard

- Tempered aluminum die-formed plate fins available with corrugated or flat surfaces with a waffle edge and extrudead fin collars

- 18-gauge G-90 galvanized sheet steel casing

- Coils may contain as many as 12 rows deep with a single fitl pack

- Split fin design contains its many as 24 rows deep

- Heights up to 525″ in a single fin

- Fin spacing ranges from 4 FPI to 14 FPI

- Tubes arc mechanically expanded into the fins

- Tube sheets are full coil depth and die-formed and full collared

- Connections can bc exactly match to existing coil or piping arrangement

- leak tested in a water

Chilled Water and DX Coil custom option

- Special fin materials

- Special copper tubing

- Special casing depths

- Stainless steel casings

- Insulated coil boxes

- Drain pans

- Pitched casings

- Steel MPT connections

- leak-lesled in a water tank

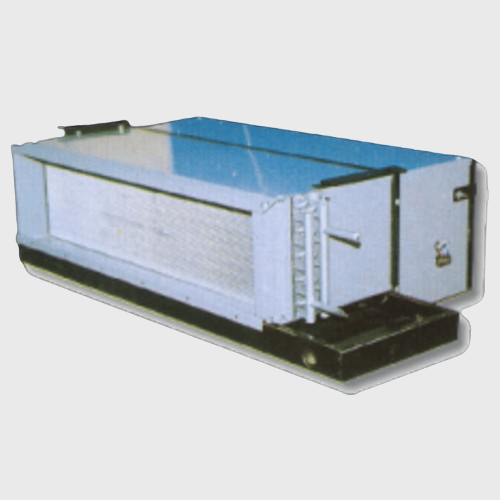

Fan Coil Unit

A Fan coil unit (FCU) is a simple device consisting Of a healing or Cooling coil and fan.ll is part oran HVAC system found in residential-commercial,and industrial buildings-Typically a fan coil unit is not connected to ductwork,and is used 10 control the temperature in the space where it is installed, or serve multiple spaces. It is controlled either by a manual on/off switch or by thermosIat Due 10 their simplicity, fan coil units are more economical to install than ducted or central heating systems with air handling units. However, they can be noisy because the ran is within the same space. Unil configurations are numerous including horizontal (ceiling mounted) or vertical (floor mounted),

Construction Capability

tube size “3/8”, “1/2”, “5/8”

main type of overall fan coil unit. Tube and fin material: Aluminum Copper and stainless steels

Headers : M.S Copper, galvanized and stainless Steel

Type of fan coil units

There are three type of overall fan coil unit

1.fan coil unit with supplementary air

2.water distribution, 2-pipe

3. water distribution, 4-pipe

fan coil unit with supplementary air

According to Mechanical and Electrical Equipment for Buildings (EMEB), a Fan Coil Unit (with supplementary air) is a “below-window unit. -which moves the room air as it provides either heating or cooling, Centrally conditioned, tempered fresh air is brought to the space in a constant-volume stream; the fan moves both fresh and room air across a coil that either heats or cools the air, as required.” In addition, Fan Coil Units have a flexible installation. and may be located in arrangements other than below-window, as required.

water distribution, 2-pipe

2-pipe line system allow either heating or cooling. one pipe is for supply water . and another is for return. therefore , only hot or cold water can be distributed at any given time

water distribution 4-pipe

a 4-pipe line system allow heating and cooling take place in same time in different location with supply pipe and return pipe for hot water and another set for cold water. A 4-pipe system provide greater flexibility of control

fan coil unit components

1.coil

2.fan with motors

3.air filter

4.controls

5.piping

6.condensate drainage piping

7.outside air grills

Type of installation

Fan Coil Units may be installed in a variety of positions.

L Vertical

- Horizontal

3, Ceiling installation

- Below-window placement

These installation options allow for a variety of placements within a structure

Typical uses

Fan Coil Units are a good choice for structures that have rigidly separated spaces, These include,”

- Dorms

- Apartment Buildings

- Hospital standard patient rooms

Places where a Fan Coil would not be advantageous:

Buildings that have adjustable space arrangements.

Buildings that are required to meet higher filter standards, including;

1.Hospital isolation rooms

2. Laboratories

Advantages

l . An advantage of the 4-pipe system is that it allows control of individual spaces.

- Fan Coil Units require less construction space than systems that require ductwork, (ASC)

- Fan Coil Units allow ror very little air mixing Trom one unit to another, which is a benefit where air contamination is a concern. (EMEB)